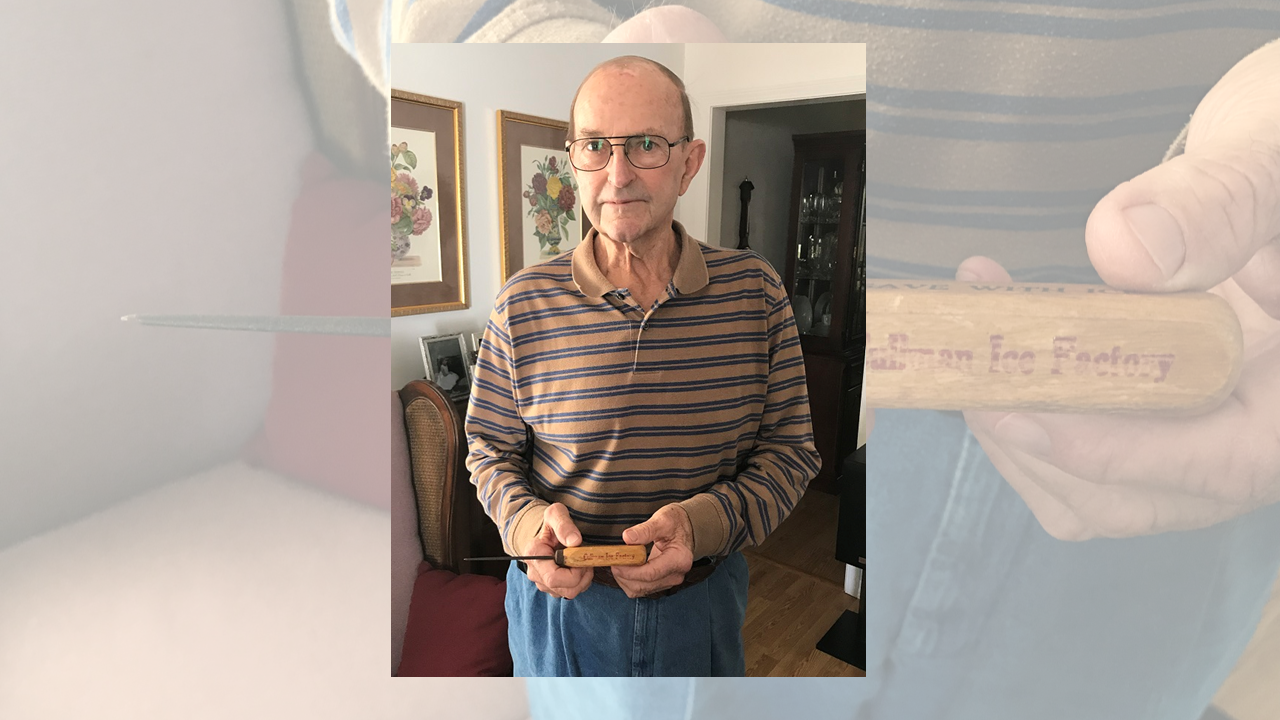

John Frutiger shows off his ice pick he saved from the summer of 1962 when he worked at the Cullman Ice Factory. (Christy Perry for The Cullman Tribune)

John Frutiger graduated from Cullman High School in 1962 with plans to attend Florence State that fall. Rather than spend his summer hanging out at The Globe and cruising to the Mug and Cone with his classmates, Frutiger was thinking ahead to college.

He was offered a job by Mr. Tom Gilley at the Cullman Ice Factory. It was 12 hours a day, seven days a week and paid $1.25 an hour. Knowing he would need spending money for college, Frutiger gladly accepted.

Ice wasn’t available at every store back then, and it was before the days of refrigerated trucks. The Cullman Ice Factory was originally built on First Avenue Southeast in 1895 by E. Hauk. The Hauk family lived above the factory. By 1962 the Gilley family operated the business.

Frutiger described the job as, “making ice, pulling ice and loading bunker trucks. Back then trucks had bunkers loaded with ice with fans blowing to keep the truck cold. There were trucks of corn and we would ice the corn to keep it from going bad before the trucks headed up north.”

The Cullman Ice Factory made 300-pound and 1,000-pound blocks of ice. Besides producing ice for bunker trucks, they supplied Goldenrod and other businesses with ice. With the only vending machine in Cullman, it was the first place a person could purchase a 10-pound bag of crushed ice.

Frutiger recalled, “On the 4th of July, they’d be lined up all the way around the block waiting to get crushed ice. It cost a quarter.”

Frutiger worked every day from 5 p.m. until 5 a.m. It was just he and his coworker Tommy Tyson and they worked well together.

He said, “We got in a rhythm catching those blocks. I was very stout and strong. I’d catch a 75-pound block of ice in the air with the tongs and put it over in the bunker. We would stack blocks of ice 15 feet high. Up front was two large vats full of brine water and ammonia pipes ran through there. It’s what chilled it.

“After 24 hours, the ice was ready. We would use tongs and pick the ice up, run hot water over it and dump it out of the metal containers it was made in. The trick was to get it on its side so you could work it, so you could slide it. You had to hit it on the edge. If it hit on the surface, it would explode and it would be ruined. A 1,000-pound block was probably 6-feet tall. The floor was real smooth so one person could slide the block.”

Frutiger still holds on to his ice pick from his summer working at the ice factory. The inscriptions on the four-sided handled are still visible. The sides read Cullman Ice Factory, Ice and Coal, Save with Ice, and 34 & 22. The numbers were the phone numbers. The ice pick was used to break the blocks down.

Frutiger explained, “We would chip it up into different sizes. A lot of the highway department people would come get ice, 15-pound blocks of ice, and put it in their metal containers for the workers that day. To chip the ice, you just make a line in the ice and pop it. It’s easy to work with once you learn the technique.”

Frutiger remembers his summer job fondly, smiling, “I guess I can say I’m the last living person to work in the ice factory.”

Frutiger left for Florence State in September of 1962. He enjoyed his college years and said, “It was the time of my life.”

After graduating, Frutiger returned to Cullman where he worked for the health department for 31 years.

Copyright 2019 Humble Roots, LLC. All Rights Reserved.