HANCEVILLE, Ala. — Wallace State Machine Tool Technology/CNC students recently fabricated hardware for the National Aeronautics and Space Administration (NASA) to send to the International Space Station, providing them with valuable hands-on experience and enhancing their resumes as they pursue careers in machining and manufacturing.

Through a partnership with NASA’s High Schools United with NASA to Create Hardware (HUNCH) program, Wallace State students have been tasked with machining hardware items, such as a pusher plate, which will have real-world applications in space. The program emphasizes precision and quality, as these components will undergo rigorous testing to meet NASA’s ambitious standards for space flight. Throughout the process, students learn about NASA’s quality assurance protocols and the importance of thorough safety documentation, making them responsible for producing work of the highest quality.

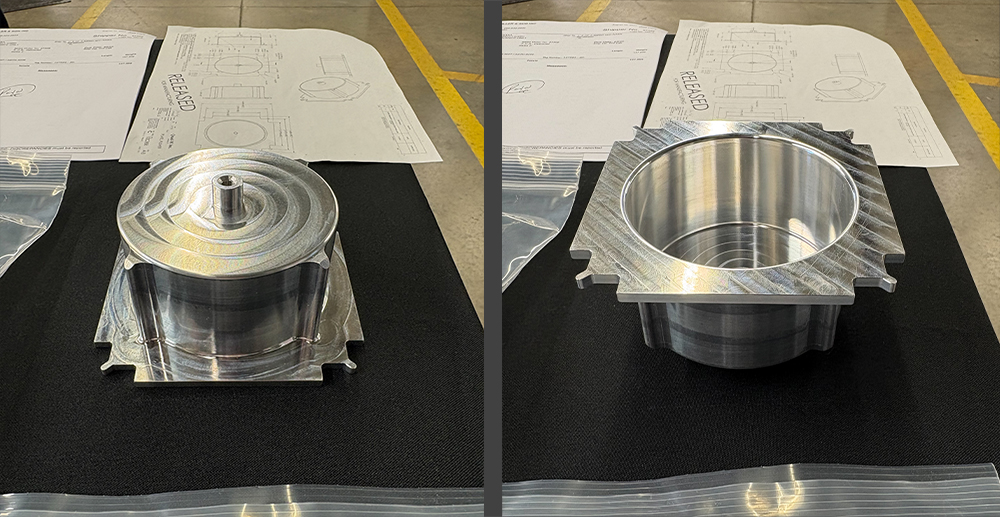

Wallace State students’ precision and craftsmanship have garnered praise from NASA, as their work on key components for satellite deployers will soon have a real-world impact in space. CubeSats, a class of nanosatellites, are cube-shaped research spacecrafts. These small satellites are launched into Earth’s orbit from the International Space Station using specialized deployers, which includes the hardware fabricated by Wallace State students. Bill Gibson, hardware support specialist for the NASA HUNCH program, highlighted the importance of the students’ contributions and commended their ability to meet NASA’s rigorous standards.

“Wallace State Community College’s Machine Tool Technology program recently delivered 20 parts to the NASA HUNCH program to be used in the assembly of miniature satellite deployers used to launch CubeSats into Earth’s orbit from the International Space Station. The CubeSat Deployer is a 32-inch-long square tube loaded with a 50-inch cube-shaped satellite loaded inside. The 20 parts Wallace State produced are called the pusher plate and it is the critical internal component that pushes the CubeSat down the 32-inch-long tube and into space,” said Gibson. “Wallace State had 100 percent of these parts pass the rigorous inspection required by NASA, which will receive a special plating in Houston before being used in the assembly of CubeSats. Wallace States Machine Tool Technology instructors and students are to be commended for taking on this very difficult task and for doing such an excellent job. On behalf of the NASA HUNCH program, we offer a huge thank you.”

This partnership provides Wallace State students with an unparalleled opportunity to gain practical experience in their field while building their confidence and exploring potential careers in machining, engineering and other STEM disciplines. Wallace State’s Machine Tool Technology/CNC Program boasts a strong track record of graduate success, with high placement rates in area industries. This collaboration with NASA HUNCH is expected to enhance students’ skills and further solidify the program’s reputation for producing highly qualified machinists.

Wallace State Machine Tool Technology Department Chair Justin Burnett emphasized how this collaboration benefits students by offering hands-on experience and insights into industry standards.

“We are proud to be one of the first college programs to partner with HUNCH, offering our students an extraordinary opportunity to work on high-level, real-world projects that go beyond typical school assignments,” said Burnett. “This experience not only sharpens their skills but also prepares them for success in the workforce with a deeper understanding of industry expectations.”

Those who successfully complete the Machine Tool Technology/CNC Program at Wallace State earn multiple short-term certificates, an Associate of Applied Science (AAS) Degree, National Institute for Metalworking Skills (NIMS) certifications and National Coalition of Certification Centers (NC3) Precision Measuring certifications, along with countless hours of hands-on experience needed to succeed in the machining field.

Wallace State recently received a $50,000 grant from the Gene Haas Foundation to provide scholarships to students in the CNC program, continuing to support the education and training of future machinists. The college remains committed to addressing the skills gap in the manufacturing industry by providing students with the resources and opportunities needed to excel in their careers.

The future looks bright for Wallace State students, who are not only working on projects that will make their way into space but who are also securing the skills and experience needed to thrive in Alabama’s manufacturing sector and beyond.

The WSCC Machine Tool Technology program will host an open on Tuesday, Nov. 19 from 5 to 7 p.m., in the Herb Black Machining Building on the Hanceville campus. The event is open to anyone interested learning more about the program, which offers both day and evening class options.

For more information about the Wallace State Machine Tool Technology program, contact Justin Burnett at 256-352-8235 or email machinetool@wallacestate.edu.